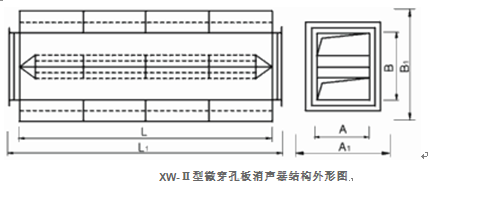

WKW-ⅡMicroperforated plate muffler

1. Product description

The microperforated plate muffler is an impedance composite muffler in terms of sound muffler principle. The muffler adopts metal structure instead of porous sound absorbing material, which is suitable for special environment such as high temperature, high speed airflow, water vapor, dust and so on. The micro-perforated muffler does not use any resistive sound absorbing filler, and adopts the structure of micro-perforated multi-cavity. The high-pressure airflow enters the cavity through multiple flow control in the muffler, and the audio frequency of the original airflow is changed step by step. Low resistance loss, wide noise elimination band, dust free when working. Not afraid of oil mist, moisture. Resistance to high temperature, high speed air shock. The principle of sound absorption and noise reduction for medium and high frequency broadband characteristics with good effect, the principle of sound reduction for resistance and noise reduction for low, medium frequency and pulse characteristics with good effect, as well as the micro-perforated muffler and impedance composite muffler. Pipeline muffler products are mainly used in the power generation sector of the boiler, steam turbine and other thermal equipment steam emission effective sound elimination. Based on the sound structure of micropore, the muffler has both resistance and anti-resonance. This muffler can be subjected to the impact of higher airflow speed, resistant to high temperature, not afraid of water and moisture, can withstand certain dust. The noise attenuation of the microperforated plate muffler is 10-25db (A).

2, use

Widely used in the power generation industry such as boiler, steam turbine and other thermal equipment steam emission, high noise workshop and other places.