WKDMCSeries single pulse jet bag filter

An overview,

WKDMC series single pulse bag filter is widely used in mining, electric furnace smelting, machinery manufacturing, chemical products, cement building materials, grain processing and other industrial and mining enterprises warehouse top, bottom and local dust source. It has the advantages of small volume, large air volume, compact structure and convenient use. The structure is mainly composed of fan, box, ash discharge device, control system, etc., all of which are placed in a box made of circular steel plate, the baking paint is rust-proof, the appearance is beautiful, the structure is scientific, the operation is convenient and reliable. The lower part of the unit and flange are directly connected to the warehouse roof, warehouse, belt transport and other dust removal equipment, dust recovery

Ii. Working principle

Dust gas enters the box through the air inlet, and the purified gas filtered by the filter bag is directly discharged by the fan. With the increase of filtering time and there are more and more attached to the filter bag dust deposition, increase the resistance of filter pocket, the parameters of gradually reduce, to work, to control the resistance within a certain range, must be carried out on the filter bag dust, soot triggered by pulse controller order of each control valve open pulse valve, air bags of compressed air instantaneous pulse valve to each hole jet spray torch into the filter bag, filter bag instant swelling, make the product attached to the surface of the filter bag dust fall off, filter bag be regenerated. The dust falls into the dust bucket and is discharged through the ash valve. Thus, the dust deposited on the filter bag is periodically pulsed to clear the dust, so that the purification gas can pass through normally, and the dust removal system can be operated.

Three, technical parameters

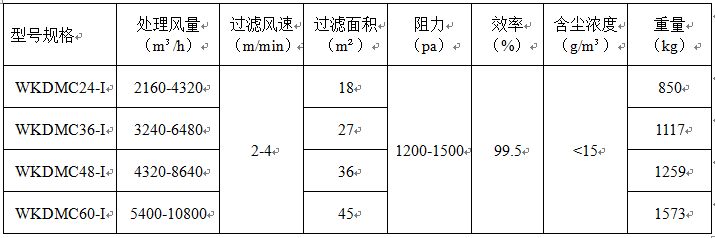

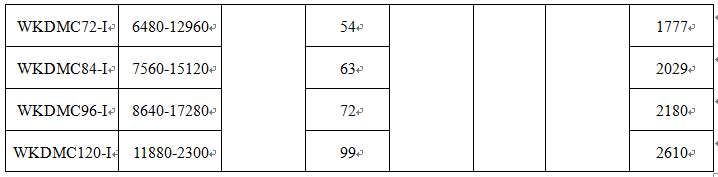

(1) wkdmc24-120i pulse jet bag filter (roof type)

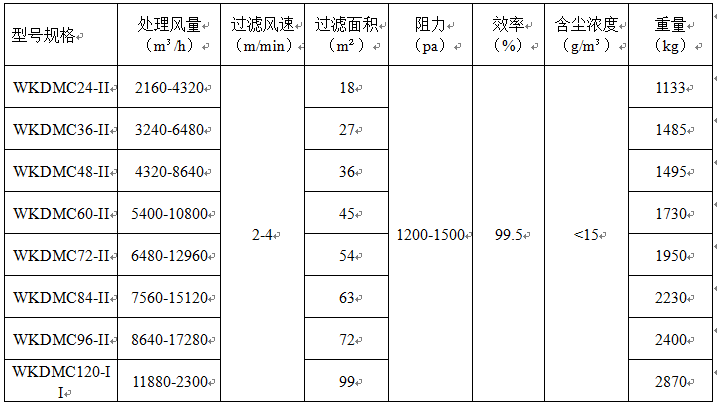

(二)WKDMC24-120II

Pulse jet bag filter